Environmental commitments

Located in the heart of a large forest region, along the river Doubs, Papeterie Zuber Rieder is respectful of the surrounding eco-system, while guaranteeing a high level of Quality.

Papeterie Zuber Rieder is committed to implementing an improvement strategy to limit its impact on the environment.

Papeterie Zuber Rieder meets the requirements of the international standards ISO 9001 and ISO 14001.

Papeterie Zuber Rieder's environmental commitments aim to:

- minimise water and energy consumption,

- improve waste management and recycling,

- protect biodiversity.

An action plan has been deployed within the company to preserve the planet's resources. Papeterie Zuber Rieder encourages its employees in this approach through specific training on respect for the Environment within the company.

Energy management

As part of a sustainable development approach, Papeterie Zuber Rieder controls and anticipates its energy consumption. The company invests in its manufacturing process and also in all its premises in order to achieve better energy efficiency. For example, the actions implemented at Papeterie Zuber Rieder have resulted in:

- An optimization of steam consumption during the manufacturing process by installing a new hood and new more efficient cylinders

- An improvement in the regulation of the hot air temperature in the pre-drying area in order to limit CO2 emissions

- A reduction in electricity consumption linked to manufacture lighting of more than 25% thanks to the installation of LEDs.

All staff are also regularly made aware of the need to reduce the company's energy impact.

Thanks to the continuous improvement of its energy performance, Papeterie Zuber Rieder is certified ISO 50001, the world reference in the field of energy management.

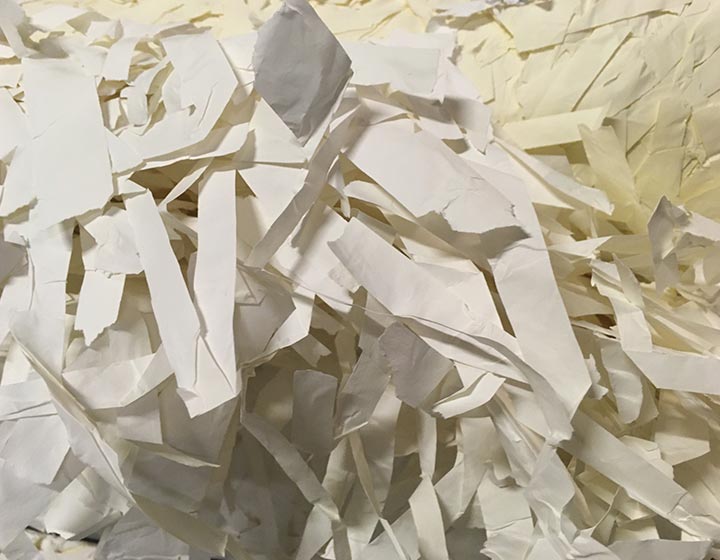

Waste management

Papeterie Zuber Rieder's Environmental policy aims to minimize the production of waste and to improve its recycling: reuse of production waste as a raw material, recycling of non-conforming paper, sorting of downgraded paper and packaging, and sending to dedicated channels.

Papeterie Zuber Rieder has implemented a strict policy on waste sorting management in order to reduce the tonnage of waste incinerated and has obtained results such as:

- A 60% reduction of its non-recyclable waste thanks to selective sorting in only 1 year

- A recovery of bio-waste with the installation of a compost near the company's lunch room

The company monitors and controls the rate of recovery of its waste in order to challenge and encourage its employees to recycle rather than eliminate. Teams are regularly informed about the importance of waste sorting through awareness campaigns.

Water management

The paper manufacturing process is very complex and requires efficient and effective treatment of the wastewater to achieve good results. That is why Papeterie Zuber Rieder has its own wastewater treatment plant to treat and discharge water that complies with environmental regulations:

- 20% reduction in water consumption in times of drought

- Participation in the production of biogas (gas produced by the fermentation of organic matter) through the methanisation carried out during the recovery and use of sludge from treatment.

Forestry management

In order to meet the challenge of preserving the world’s natural resources, and more specifically forests, Papeterie Zuber Rieder is certified FSC® (Forest Stewardship Council®) and carries out rigorous monitoring of its chain of custody. Responsible forest management is an approach to environmental, social and economic development "which aims to meet the needs of the current generation without harming the ability of future generations to meet their needs". Our commitment is to comply with the criteria defined in FSC® standards, and in particular we do not to use paper pulp that is derived from :

- illegally harvested wood

- wood harvested in violation of civil and traditional rights

- wood from forests where management activities threaten conservation values

- wood from forests that have been converted to plantations and are not used as forests

- timber from genetically modified forests.

Our certificates

- ISO 9001 - Continual improvement of our quality management system

- ISO 14001 - Continual improvement of our environmental management system

- ISO 50001 - Continual improvement of our energy performance